Power Solution for Industrial Manufacturing

Load analysis of Industrial Manufacturing

1. Communication Control Equipments

Communication control equipments are applied to every part of automated production chain, including process control and monitoring, automation equipment, measuring instruments, sensors, actuators, as well as other computer-aided equipments and systems, such as PLC (Programmable Logic Controller), DCS (Distributed Control System), and industrial control computers and etc. Since communication control equipments are of large quantity, wide distribution and complex application environment, whether they can work mainly depends on the quality of power supply. The higher the degree of automation, the more high-quality power is needed. For example, usually, PLC requires power supply of 50Hz, 220V ± 10% and allowed interruption time is less than 10ms. Since the data needs to be initialized if PLC is restarted, no stop should appear during working. In practical application, PLC is very susceptible to power quality, problems such as electromagnetic interference, too high or too low voltage, power outages and etc. all will cause abnormal working condition of PLC, and eventually PLC-controlled equipments even do not work, affecting the production process. But in industrial applications, above-mentioned problems frequently happen. Therefore, control communications equipments in automatic production should be supported by on-line UPS with functions of stabilizing frequency and voltage. Computers, servers and network equipments used in facility house also face various kinds of power quality issues—data loss, error code, hardware damage, etc., thus as well require the protection of on-line UPS.

With the development of steel industry, information technology, network, e-commerce mode are applied to every field including innovation, technical transformation, quality control, supply chain and etc. in this industry, realizing informatization to enhance the competitiveness. There are three levels of infomatization: network platform, business platform and enterprise applications, and the later two are both based on the first one, thus the network construction is a top priority. And safe and reliable power support facility is the foundation of network construction. So the importance of UPS is increasingly prominent.

Solutions of power supply in industrial manufacturing:

Communication Control Equipments

Since all aspects including molten iron desulphurization, continuous casting, RH turbid circulating water, refill container, blowing oxygen, muck removal, dust extraction and water cycle all adopt PLC control systems to achieve auto control, and fluctuations and interruptions in power grid will affect quality of steelmaking, in order to ensure reliable operation of the system, UPS is a must to provide clean, continuous power. Recommended capacity is 3 ~ 100KVA.

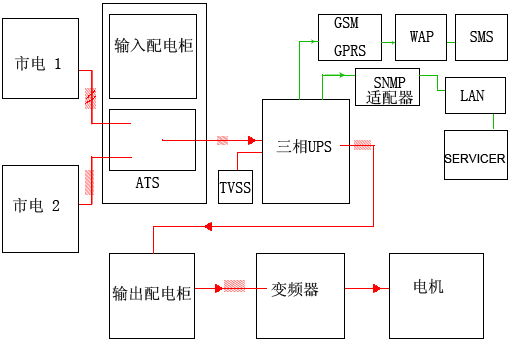

If frequency converter is equipped before motor to limit the starting current of it to a lesser extent (1 to 1.25 times the rated current), then capacity of UPS/capacity of motor can be smaller. As for this type, recommended proportion is: UPS/Frequency converter/Motor = 1.5/1.25/1. For 70KW motor, 70 × 1.25 = 87.5KW frequency converter, 70 × 1.5 ÷ 08 = 131KVA UPS can be configured.

(Combined application of UPS and frequency changer)

Information Center